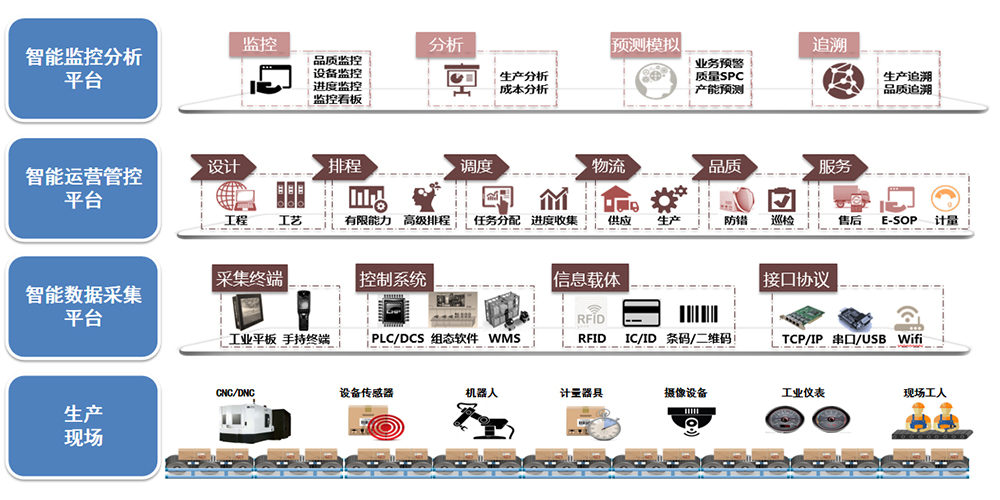

Digitalization construction goal of digital intelligence factory (application layer)

Digital construction goals of the digital intelligence factory (management level)

安全生产 ◆ Behavioral safety inspection of workshop personnel ◆ Safety inspection of equipment operation ◆ Detection of safe work areas | Reduce cost and increase efficiency ◆ Collect production equipment water, electricity and other data on a per order basis for cost analysis ◆ Flexible planning to improve personnel, equipment utilization, and utilization rates ◆ Data collection efficiency, production exception handling efficiency | Smart operation ◆ Flexible planning, intelligently adjusting workshop plans based on actual production conditions ◆ Intelligent warning of anomalies based on real-time execution data ◆ Real time data analysis, real-time presentation, and real-time decision-making | Customer satisfaction ◆ Real time monitoring of production operations (processes) by customers◆ Real time monitoring of production quality data by customers ◆ Real time monitoring of order execution progress by customers |

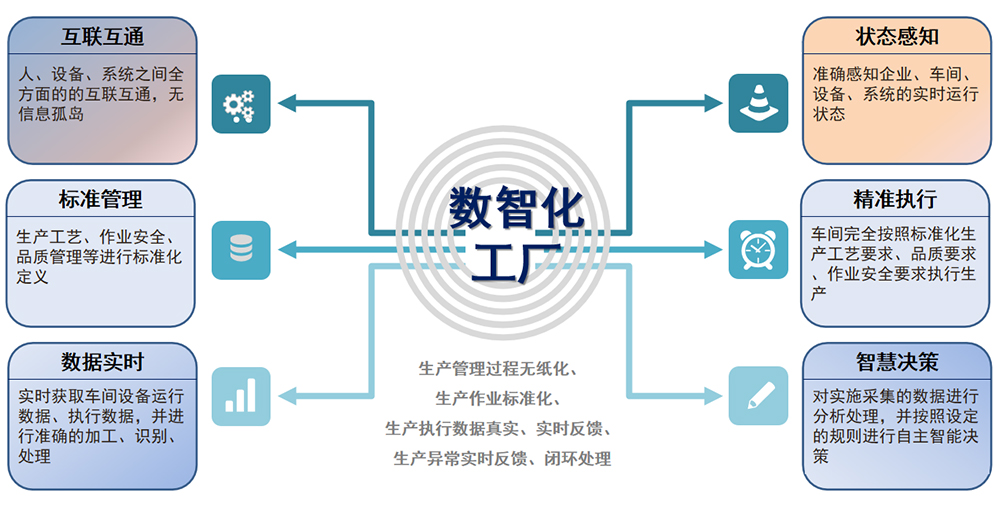

Overview of Production and Operation Solutions for Smart Chemical Plants

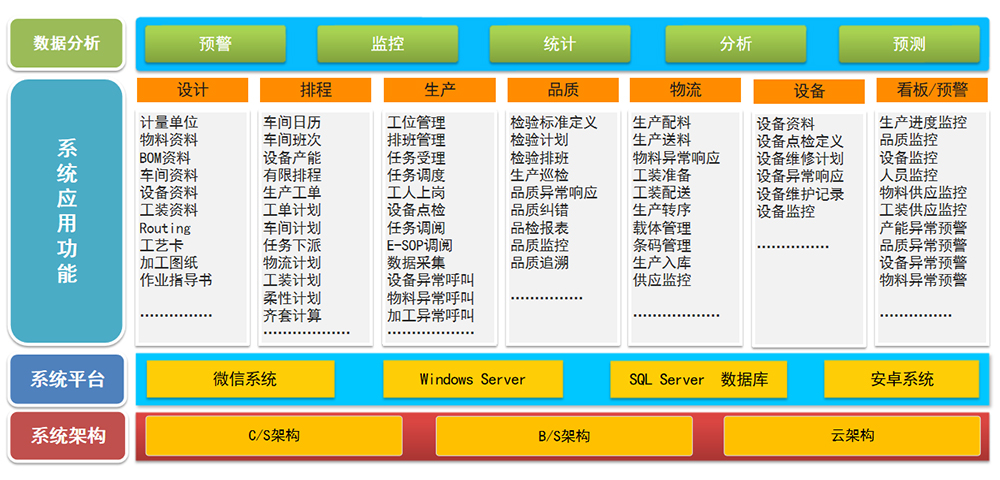

Introduction to the Functions of Production and Operation Solutions for Smart Chemical Plants

Introduction to the Functions of Production and Operation Solutions for Smart Chemical Plants

1. Equipment management ◆ Normal operation management of equipment ◆ Equipment exception handling management ◆ Equipment operation and maintenance management | 2. Technical management ◆ BOM data management for the project;◆ Production process management of the project; ◆ Process cards, operation manuals, and safety operation manuals for each process of the project; ◆ Quality inspection cards for each process of the project; | 3. Production scheduling management ◆ Production scheduling;◆ Production machine scheduling; ◆ Plan and schedule each process; ◆ Process flexibility plan; |

4. Shop floor control ◆ Each production workstation is equipped with an industrial integrated machine;◆ Real time viewing of SOP materials such as production schedules, production drawings, process cards, and operation manuals through corresponding industrial all-in-one machines; ◆ Real time feedback on operation time and progress through corresponding industrial all-in-one machines; ◆ Real time feedback and real-time calling of various abnormalities in the production process through corresponding industrial all-in-one machines; | 5. Production exception management ◆ The workstation all-in-one machine makes various abnormal calls;◆ Closed loop management of device exception handling process; ◆ Closed loop management of material exception handling process; ◆ SOP exception handling process closed-loop management; ◆ Closed loop management of homework exception handling process; ◆ Closed loop management of quality anomaly handling process; | 6.Production quality inspection management ◆ Quality inspectors can view the inspection standards for each process through mobile tablets or workstation integrated machines; ◆ Quality inspectors provide real-time feedback on inspection data through mobile tablets or workstation integrated machines; ◆ Provide a handling plan for inspection anomalies and implement closed-loop management for the final processing results; |

7. Production data acquisition ◆ Collect relevant data on the production process of rolling machines, welding machines, and testing equipment; ◆ Compare the collected data with the requirements of the process operation, and issue warnings in case of any abnormalities; ◆ Perform statistical analysis and processing on the collected equipment production data; | 8. Production data monitoring ◆ Production progress dashboard; ◆ Equipment signage; ◆ Equipment utilization rate dashboard; ◆ Production Quality Dashboard; ◆ Abnormal production dashboard; ◆ Real time production data dashboard; | 9. Production data sharing ◆ Sharing production progress data for customer viewing; ◆ Customer viewing of shared processing process data; ◆ Sharing production quality inspection data for customer viewing; |